A polymer is defined as a large network of molecules that consist of many repeat units. A polyimide is a specific type of polymer, consisting of imide monomers. Polyimides are highly desirable for their heat resistance, mechanical strength, and insulative properties.

What is an Imide?

To obtain a good understanding of what a polyimide is, first we have to understand the chemistry within it. An imide is a functional group consisting of two acyl groups bound to nitrogen. Imides are highly polar, which provides them with good solubility in polar media.

Polyimides

Polyimides are produced from diamines and dianhydrides in a two-stage process. The product from the 1ststage, a polyamic acid, is imidized in the 2nd stage using either heat or a chemical dehydrating agent to form the polyimide.

Polyimides may be thermoplastic, with a high melt viscosity requiring high pressure to form molded parts. Examples include SKYBOND® molding resins and KAPTON® films.

Polyimides may also be thermosetting, whereby imide oligomers are crosslinked into a three-dimensional network. Examples of thermoset polyimides include PMR-15® and PETI® matrix resins for advanced composites.

Polyimide Properties

Most polyimides are orange/yellow in color, and they provide excellent thermal stability, mechanical strength, electrical properties, and good chemical resistance.

Newer generations of colorless polyimides (CPI) have been recently introduced, exhibiting high transmittance and low Yellow Index for improved clarity.

Graphite or glass fiber reinforcements are often added to polyimide matrix resins to form advanced composite materials with impressive strength-to-weight ratios.

Polyimide Applications

Polyimides exhibit a range of attractive properties, which make them useful for many applications in aerospace, electronics, and industrial sectors.

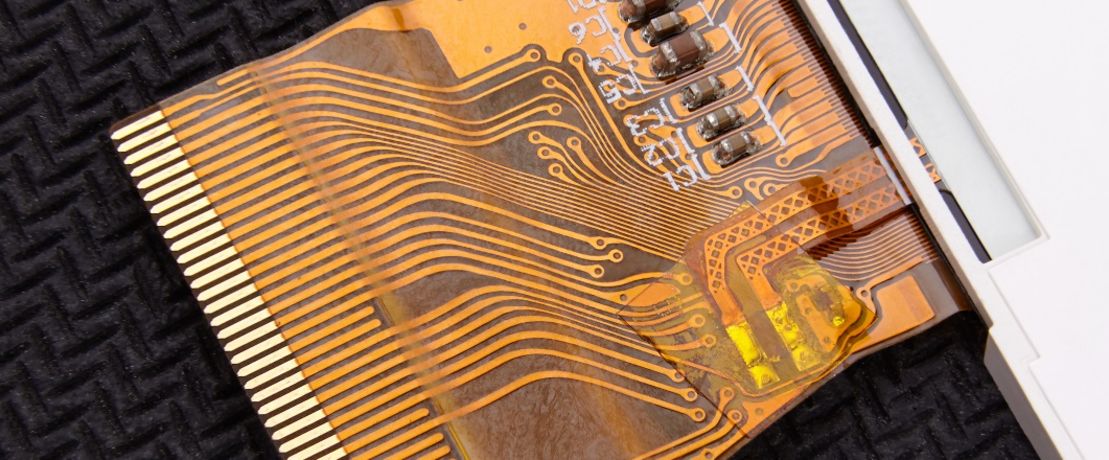

When manufacturing semiconductors and flexible printed circuits, polyimides have a variety of uses. They can be used as high-temperature adhesive, mechanical stress buffers, and as a film to support micronized circuity. They are useful in the manufacture of electronic cables as an insulating film on the magnet wire.

Polyimide composites find use in aerospace to replace metals in engine components, such as ductwork and insulation.

Polyimide fibers are woven into protective clothing for firefighters, and bags for hot gas filtration in cement kilns and power plants.

Polyimide foams are used for lightweight highly efficient thermal and acoustic insulation in marine vessels and aircraft.

Dianhydrides

JAYHAWK develop and manufacture a range of dianhydrides that are suitable for polyimide synthesis. Our products can be used to improve polyimide processing and provide property enhancements.

To learn more about fine chemical solutions, read our article: Characterizing Cycloaliphatic-containing Polyimides

If you would like any more information about how JAYHAWK dianhydrides can be used for polyimide synthesis, please contact us.

[The trade names listed herein are owned by their respective manufacturers.]